In today’s rapidly evolving manufacturing landscape, organizations strive to optimize operations and leverage real-time data for informed decision-making. SAP MII (Manufacturing Integration and Intelligence) stands at the forefront of this revolution, seamlessly connecting the shop floor to enterprise systems. In this article, we explore what SAP MII is, its key features, and how it empowers organizations to achieve manufacturing excellence.

What is SAP MII?

SAP MII, short for Manufacturing Integration and Intelligence, is a powerful software application designed to bridge the gap between shop floor operations and enterprise-level systems. It enables organizations to integrate manufacturing processes, collect real-time data, and gain valuable insights for improved decision-making.

Key Features and Functionalities

- Shop Floor Integration: SAP MII connects machines, sensors, and other shop floor devices, facilitating real-time data collection and transmission. This integration enables organizations to monitor production processes, track inventory levels, and ensure efficient resource allocation.

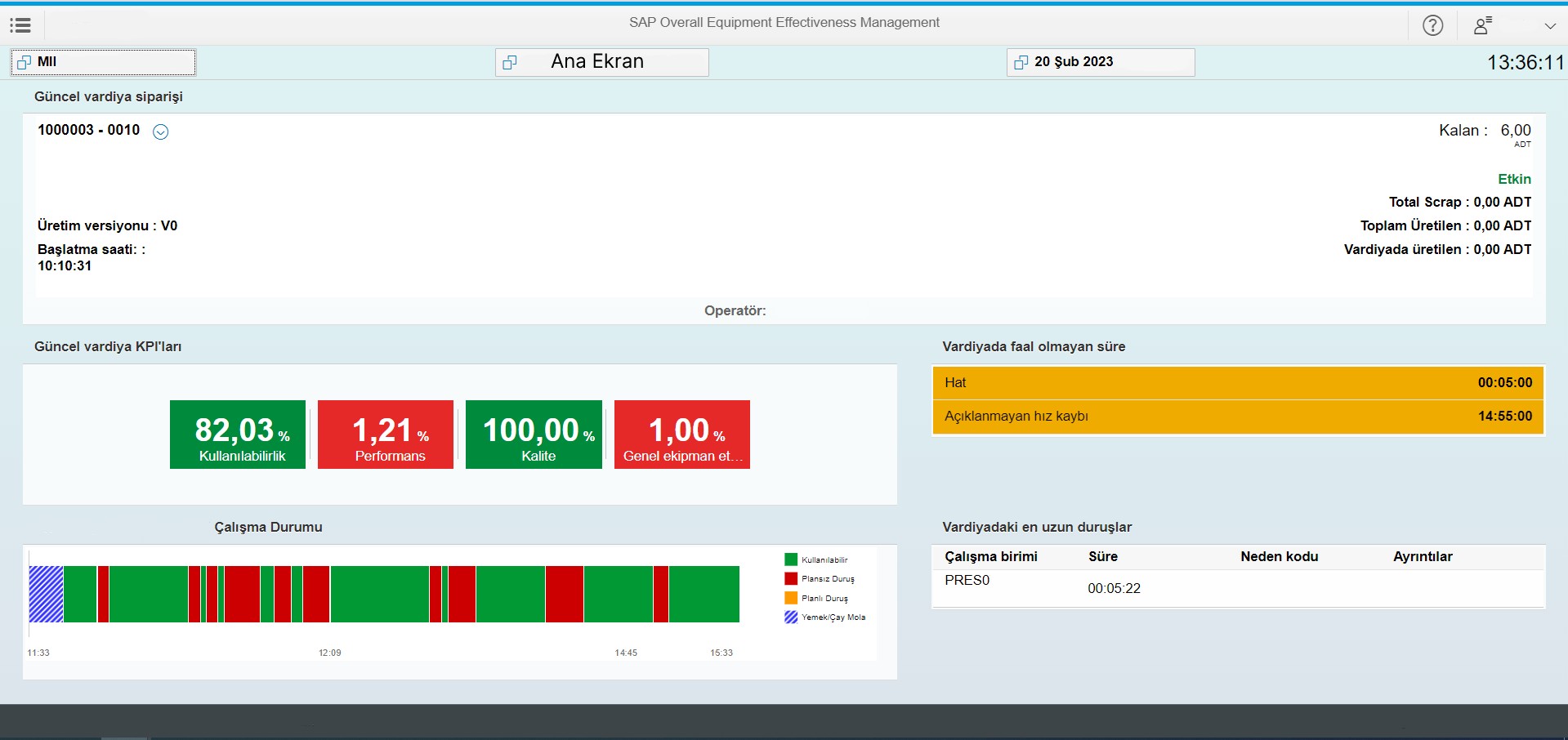

- Real-Time Data Analysis: SAP MII provides robust analytics capabilities, allowing organizations to analyze real-time data from various sources. By gaining insights into production performance, quality control metrics, and operational bottlenecks, decision-makers can proactively address issues and optimize processes.

- Production Monitoring: With SAP MII, organizations can monitor production in real-time, track key performance indicators (KPIs), and identify potential bottlenecks or downtime events. This visibility enables proactive decision-making, reducing disruptions and optimizing productivity.

- Quality Management: SAP MII facilitates quality control by integrating data from multiple sources, such as inspection systems and production equipment. It enables organizations to monitor quality metrics, implement corrective actions, and ensure compliance with industry standards.

- Integration with Enterprise Systems: SAP MII seamlessly integrates with other enterprise systems, such as ERP (Enterprise Resource Planning), MES (Manufacturing Execution System), and SCADA (Supervisory Control and Data Acquisition). This integration enables the exchange of data and provides end-to-end visibility across the entire manufacturing value chain.

Benefits of SAP MII

- Improved Operational Efficiency: SAP MII optimizes manufacturing processes by streamlining operations, reducing downtime, and enhancing resource utilization. Real-time insights enable organizations to identify inefficiencies, implement continuous improvement strategies, and drive operational excellence.

- Enhanced Decision-Making: By harnessing real-time data and analytics, SAP MII empowers decision-makers to make informed, data-driven decisions. The ability to monitor production performance, track KPIs, and identify trends enables organizations to respond quickly to market demands and capitalize on new opportunities.

- Increased Visibility and Collaboration: SAP MII provides end-to-end visibility across the manufacturing value chain, fostering collaboration between departments and enabling cross-functional decision-making. This transparency helps align stakeholders, improve communication, and drive organizational alignment.

- Scalability and Adaptability: SAP MII is designed to scale with the evolving needs of manufacturing organizations. It can be customized to specific industry requirements, integrated with existing systems, and expanded as operations grow. This adaptability ensures long-term value and future-proofing.

SAP MII empowers organizations to revolutionize their manufacturing operations by seamlessly integrating shop floor processes with enterprise systems. By leveraging real-time data, organizations can drive efficiency, enhance decision-making, and gain a competitive edge in the dynamic manufacturing landscape. Implementing SAP MII is a strategic move toward achieving manufacturing excellence and unlocking the full potential of your organization.